Introduction

MultiWeave is a textile technique for creating three-dimensional

woven structures using only warp and weft yarns. Inspired by 3D printing

and additive manufacturing, it allows for the construction of layered,

net-like, and sculptural forms through the use of temporary warp

supports. The MultiWeave technique, introduced in 2016 and

further developed through research projects

hackathons, and collaborative workshops, continues to evolve in

unexpected and inspiring directions . This paper outlines several new

developments in MultiWeave since its presentation at the Algorithmic

Pattern Salon in 2023. These advancements highlight how

weavers and designers are increasingly combining material innovation,

computational logic, and performative exploration to extend the

expressive and structural capabilities of the method. At Pallas

University of Applied Sciences, MultiWeave has become both a research

method and a practical tool for textile creation. The process emphasizes

interdisciplinary collaboration, peer learning, and DIY toolmaking,

fostering a community of experimentation. Examples from artists,

students, and designers across Europe illustrate how MultiWeave is

applied in artworks, garments, geotextiles, and furniture. By supporting

modular and open-ended construction, MultiWeave bridges technology,

craft, and sustainability—marking it as a contribution to contemporary

textile practice.

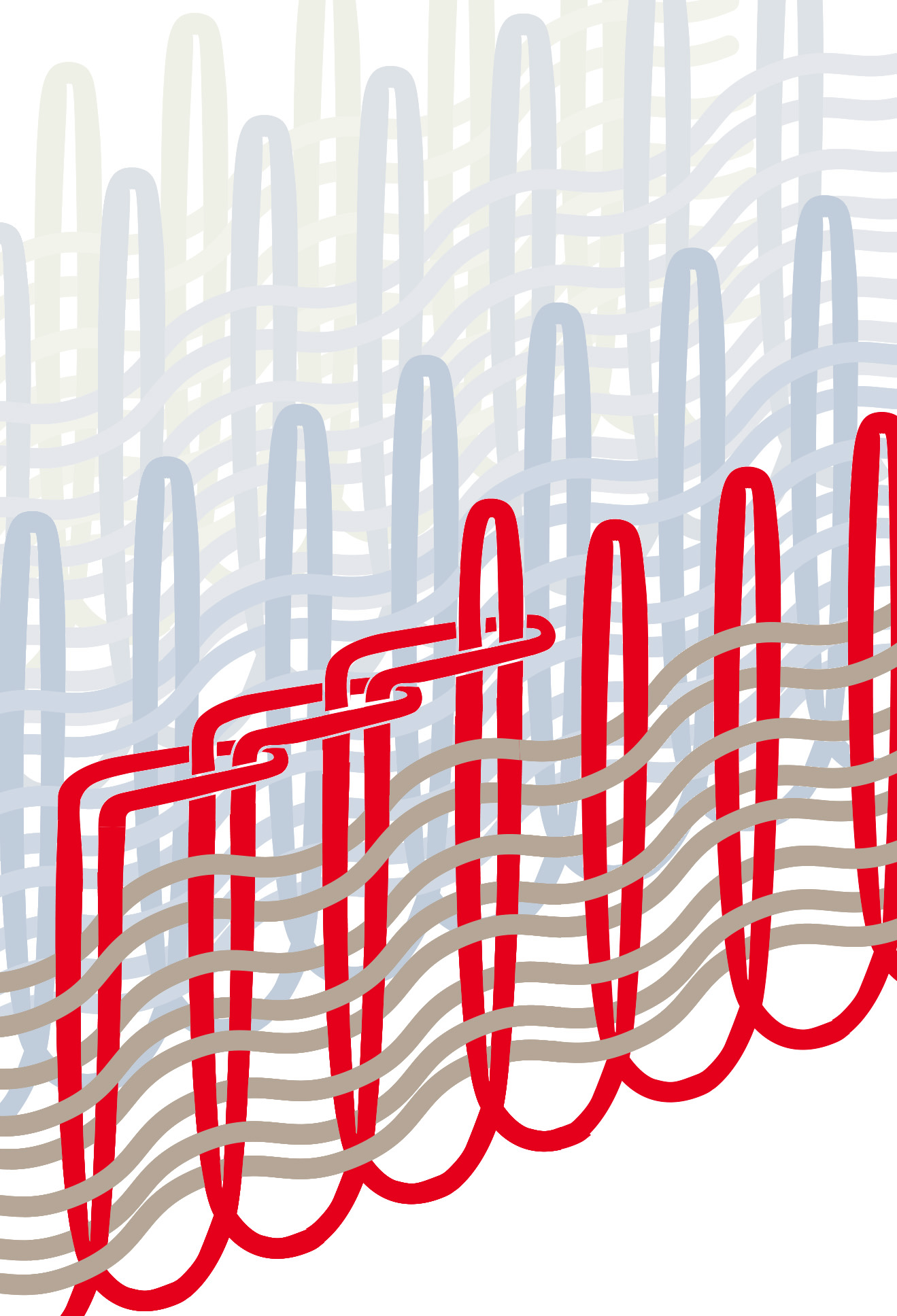

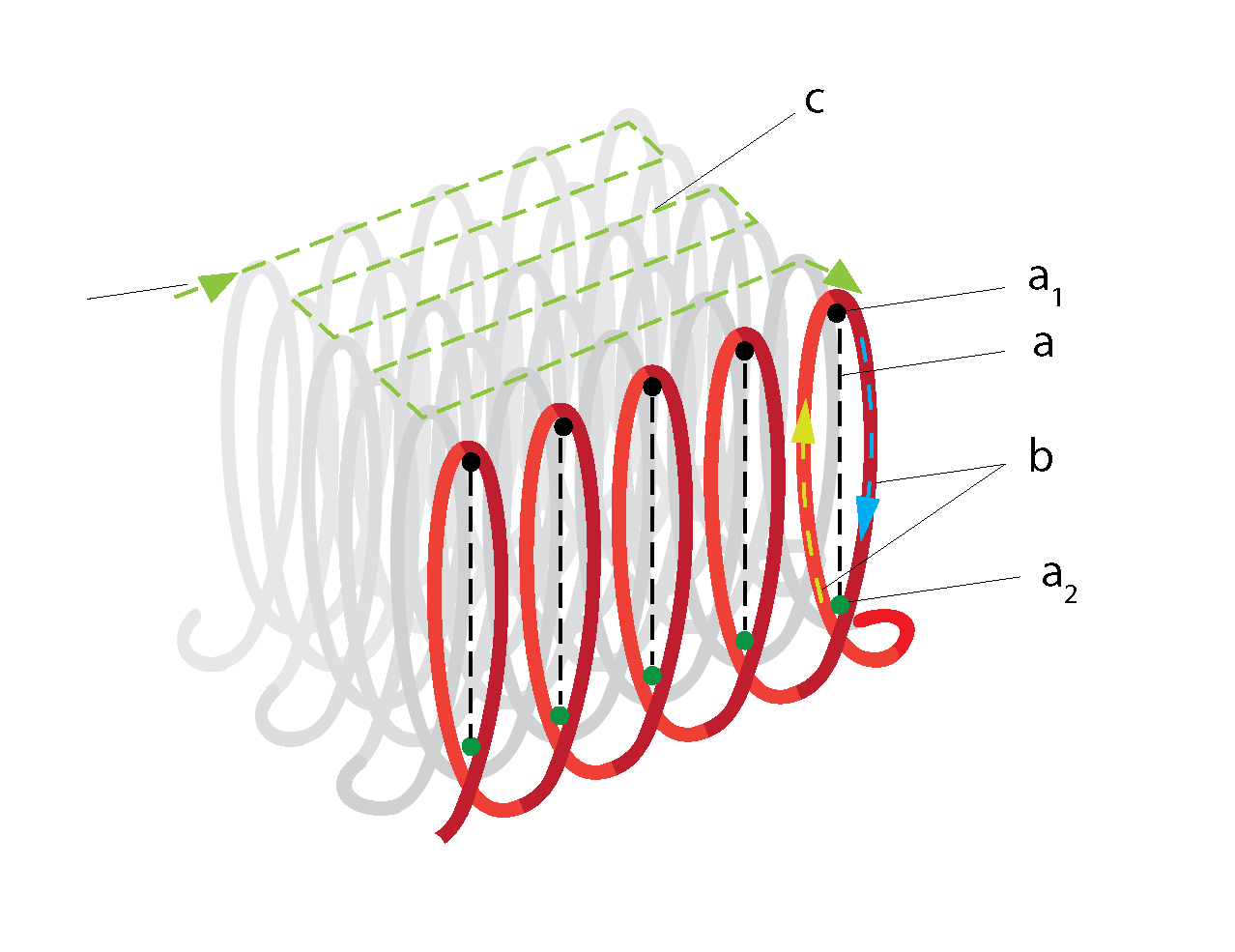

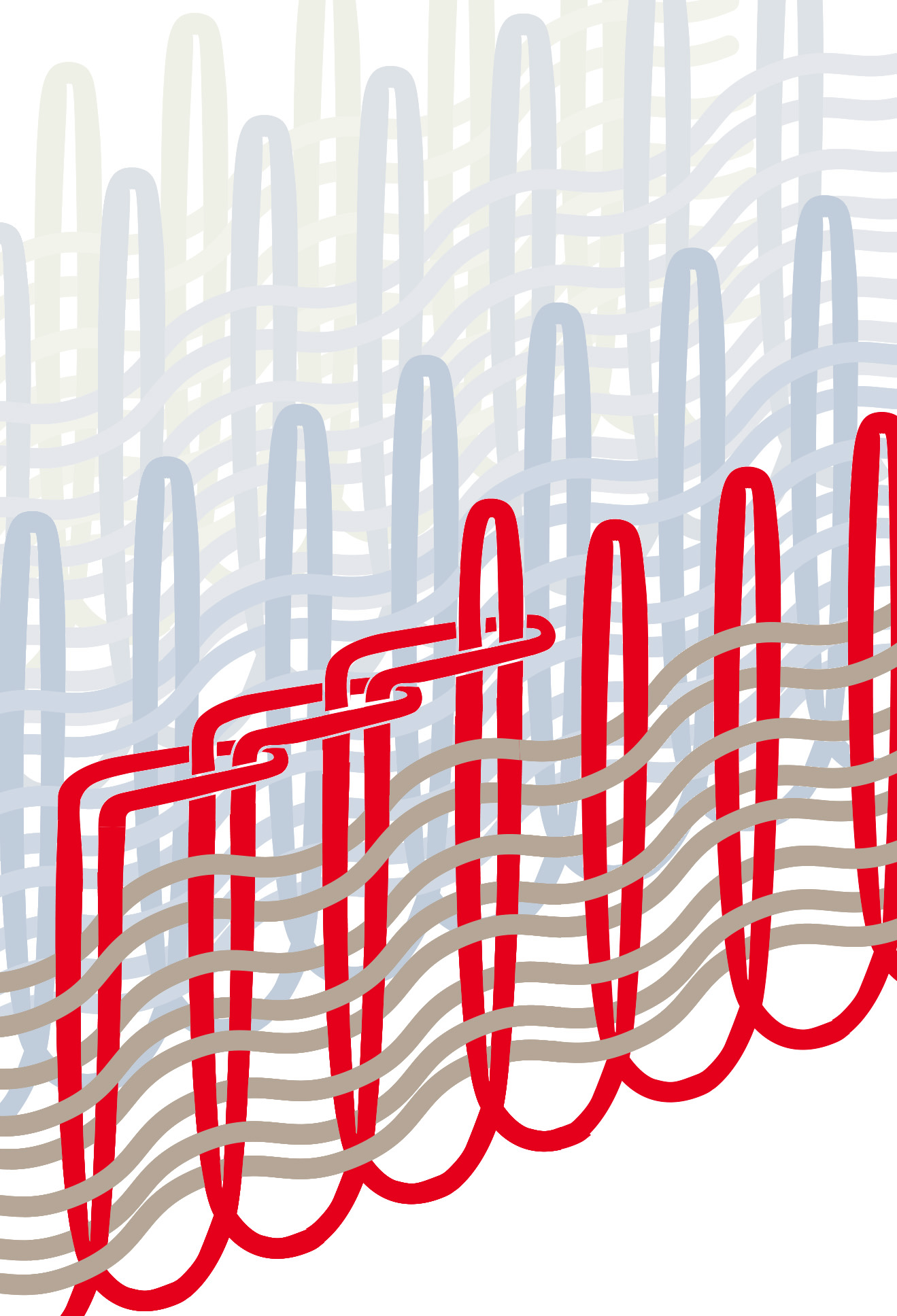

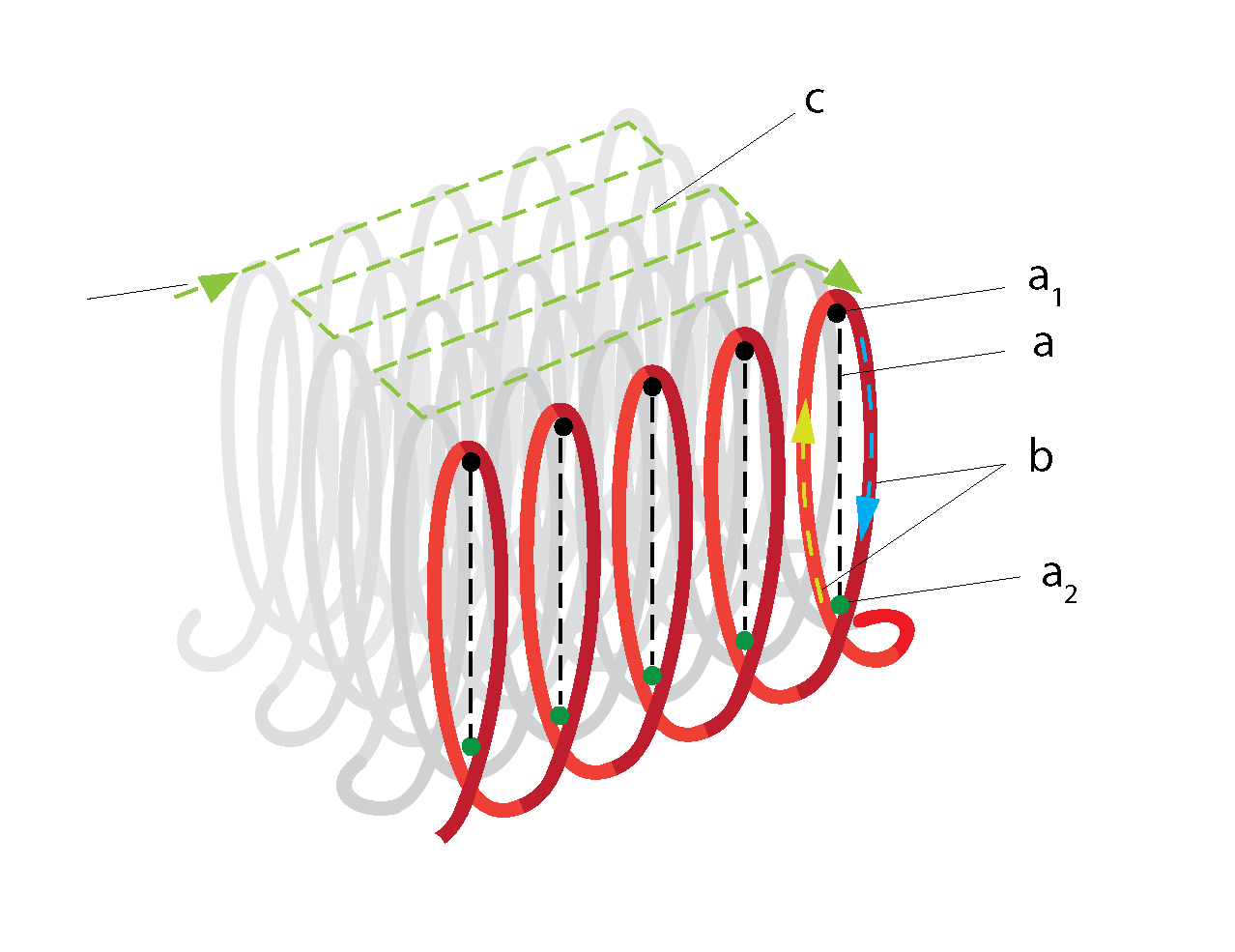

The basic idea of MultiWeaving is shown in Figures 1-3.

Figure 1: Step-by-step creation of a warp loop field. (a) Vertical

support element; (a1) and (a2) indicate the upper and lower turning

points of the warp thread around the support; (b) shows the direction in

which the warp yarn is applied across the row. Drawing by Kadi

Pajupuu.

Figure 1: Step-by-step creation of a warp loop field. (a) Vertical

support element; (a1) and (a2) indicate the upper and lower turning

points of the warp thread around the support; (b) shows the direction in

which the warp yarn is applied across the row. Drawing by Kadi

Pajupuu.

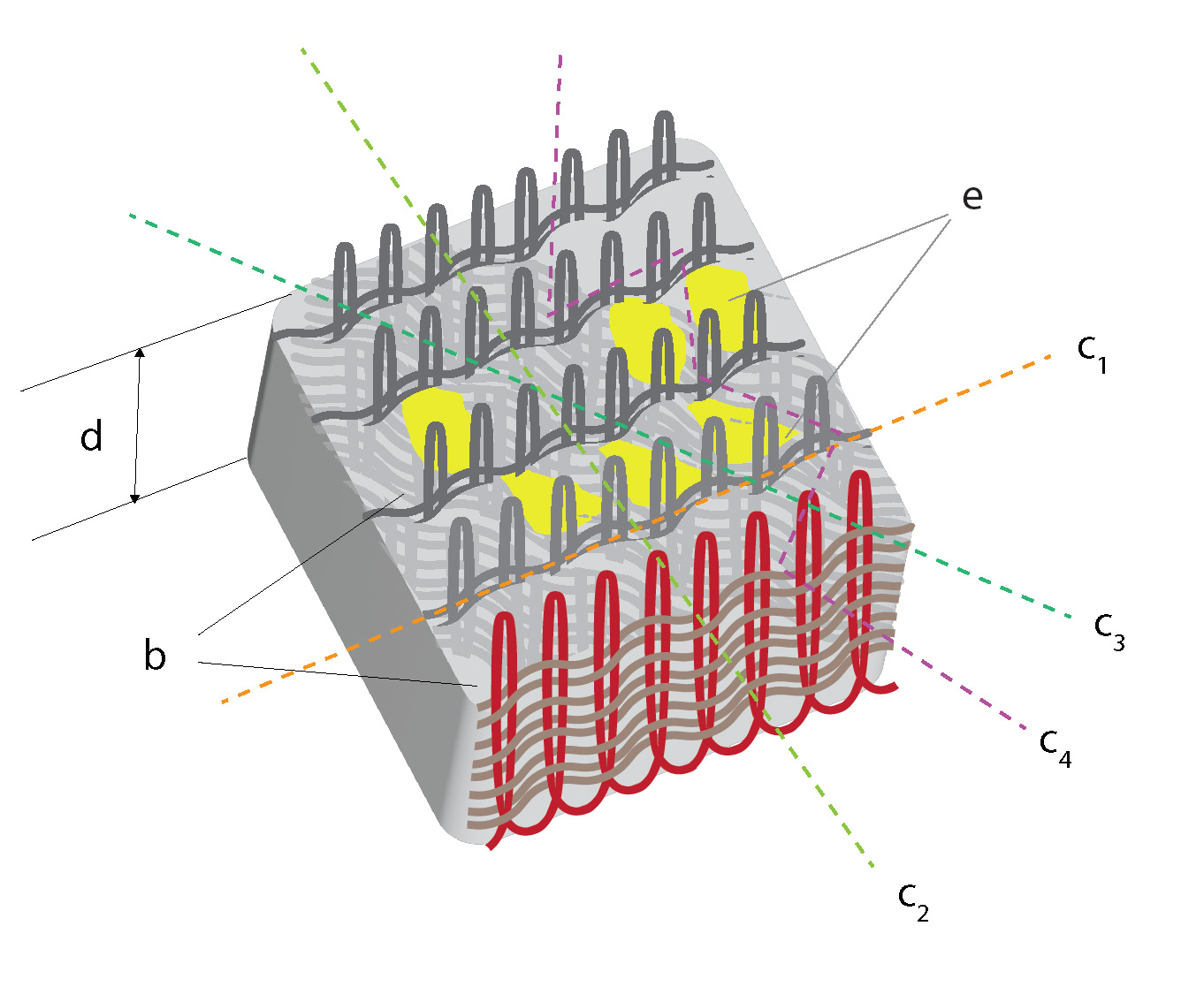

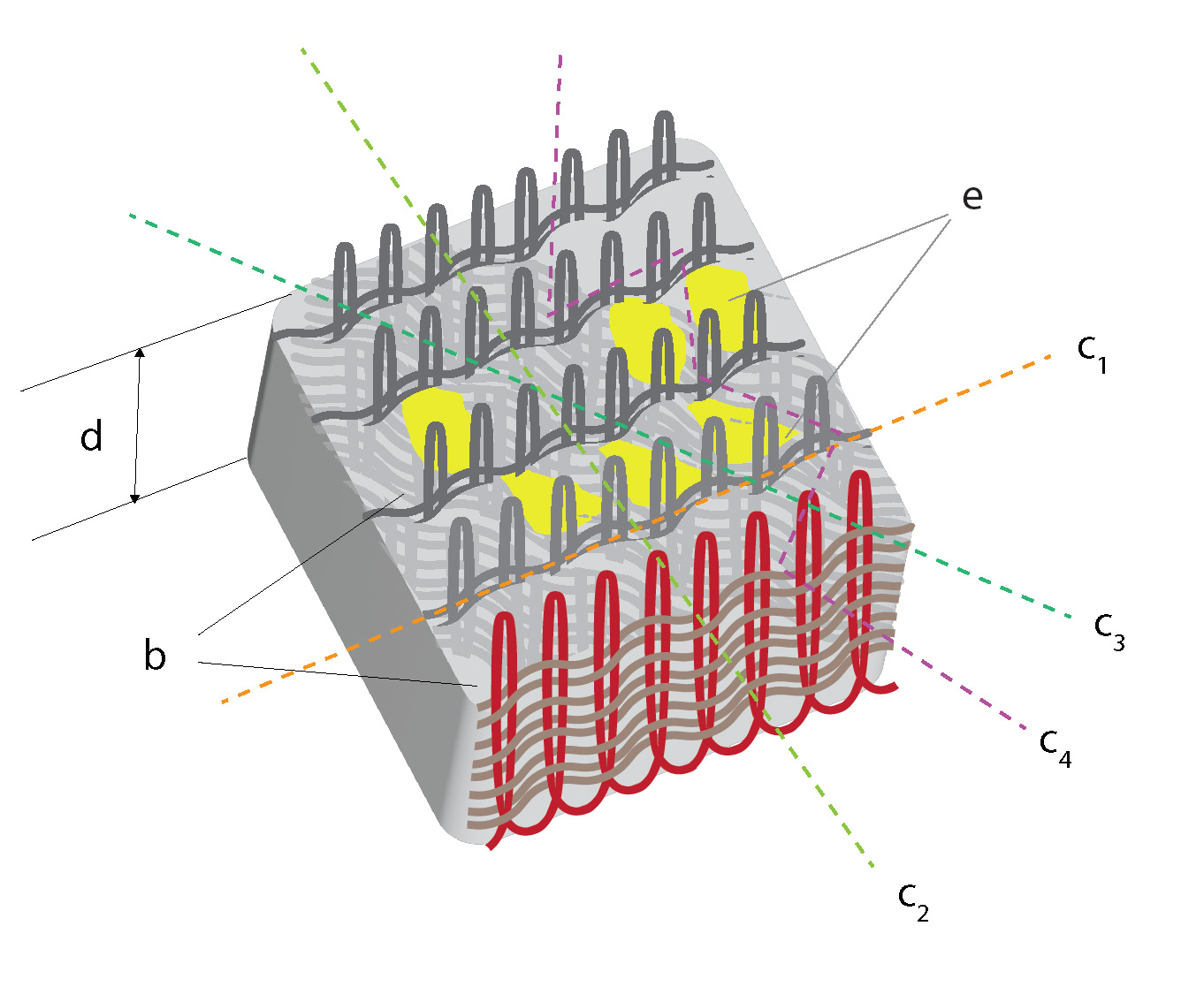

Figure 2: Diagram of weft path variations around and between warp

loops: (b) placement between warp rows; (c1) following the warp row

alignment; (c2) crossing rows; (c3) diagonal paths; (c4) zigzag

movement. The material’s thickness (d) is defined by the warp height and

number of weft layers. Weft positioning can also create vertical voids

or enclosed spaces within the structure. Drawing by Kadi

Pajupuu.

Figure 2: Diagram of weft path variations around and between warp

loops: (b) placement between warp rows; (c1) following the warp row

alignment; (c2) crossing rows; (c3) diagonal paths; (c4) zigzag

movement. The material’s thickness (d) is defined by the warp height and

number of weft layers. Weft positioning can also create vertical voids

or enclosed spaces within the structure. Drawing by Kadi

Pajupuu.

Figure 3: Final step: connecting the upper ends of warp loops to

adjacent loops to stabilize the structure. Drawing by Kadi

Pajupuu.

1. Algorithmic Sequences: Knight’s Tour in

MultiWeaving

One recent area of inquiry has been the integration of the Knight’s

Tour algorithm into the MultiWeave process. The Knight’s Tour, a classic

problem in combinatorial mathematics, describes a path that a knight

takes on a chessboard, visiting each square only once. For

our exhibition (in cooperation with Marilyn Piirsalu) in 2020 “Knight’s

Tour” at HOP Gallery, I used this principle as a basis

for determining the sequence of guiding the weft thread in a 5x5 warp

matrix. The accompanying video visualized this path through painted

horse figures leaping across the grid, each representing a warp

connection point (Figure 4, 5). This experiment opened new avenues for

algorithmically generated weaving patterns that are both aesthetic and

structurally meaningful.

{%vimeo 399983276%}

Figure 4: Knight’s Tour on a 5×5 Grid. Video created for the

exhibition Ratsurada (Knight’s Tour) by Marilyn Piirsalu and Kadi

Pajupuu, HOP Gallery, Tallinn, 2020.

Figure 5: Segment of the installation in which the paper yarn

structure follows the path of a Knight’s Tour sequence. Kadi Pajupuu,

Ratsurada (Knight’s Tour), HOP Gallery, Tallinn, 2020.

2. Dynamic Positioning: Angled Warp Rows

While warp loops in MultiWeave are usually formed in straight rows,

recent experimentation with the construction of the warp support base

has introduced greater flexibility. By cutting stripes from fluted

polypropylene sheets and inserting bamboo barbecue sticks into the

flutes, the supports can be mounted at varying angles. This allows

weavers to construct dynamic three-dimensional structures where the

orientation of each row is determined after the loops are formed. This

real-time structural decision-making enhances the tactile and sculptural

potential of the method, especially in art and design applications (see

Figure 6).

Figure 6: MultiWeave warp rows arranged in a non-parallel

configuration and fixed at various angles using a flexible support

structure. Material used for both warp and weft: paper yarn. Kadi

Pajupuu, 2024.

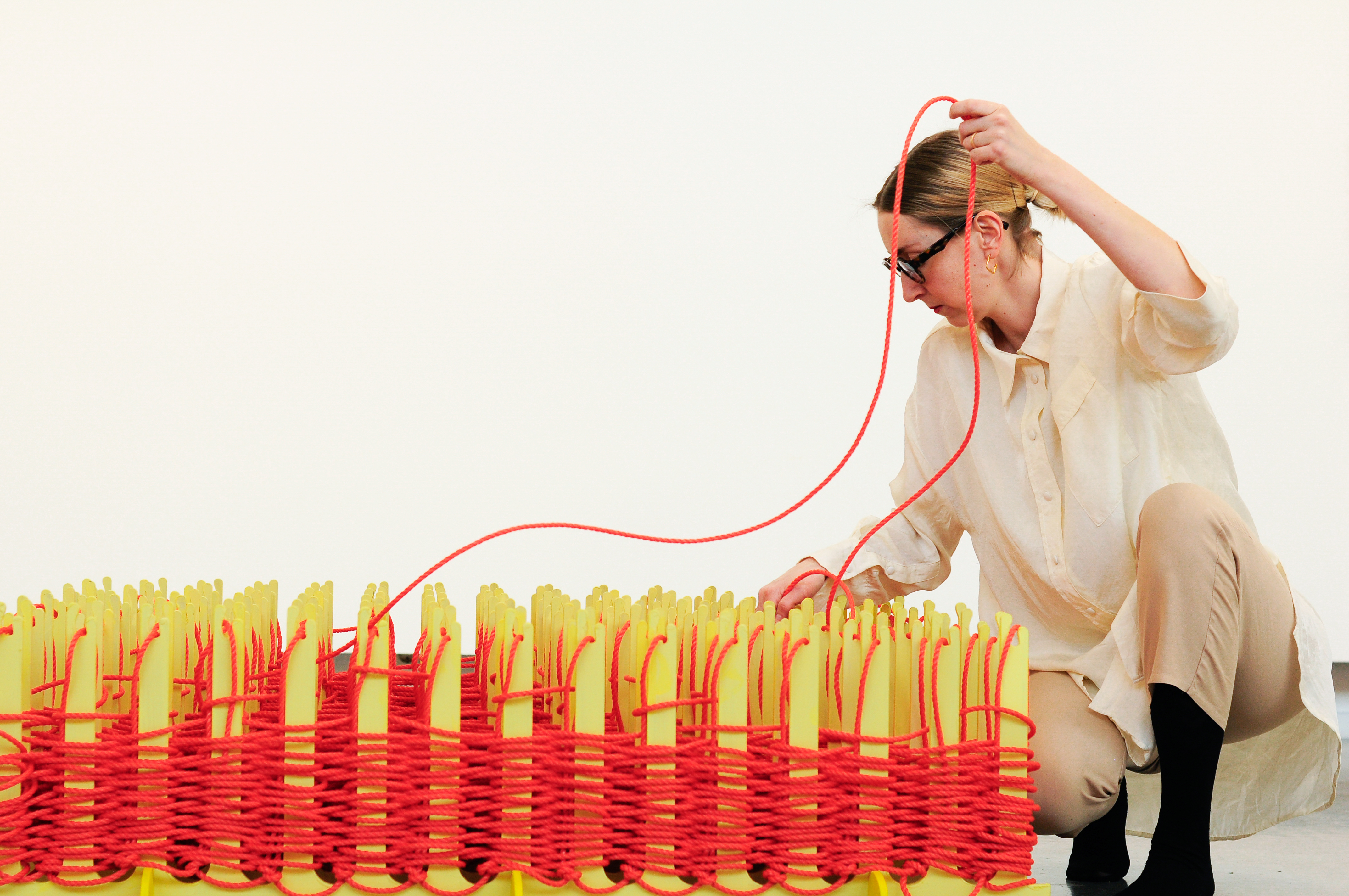

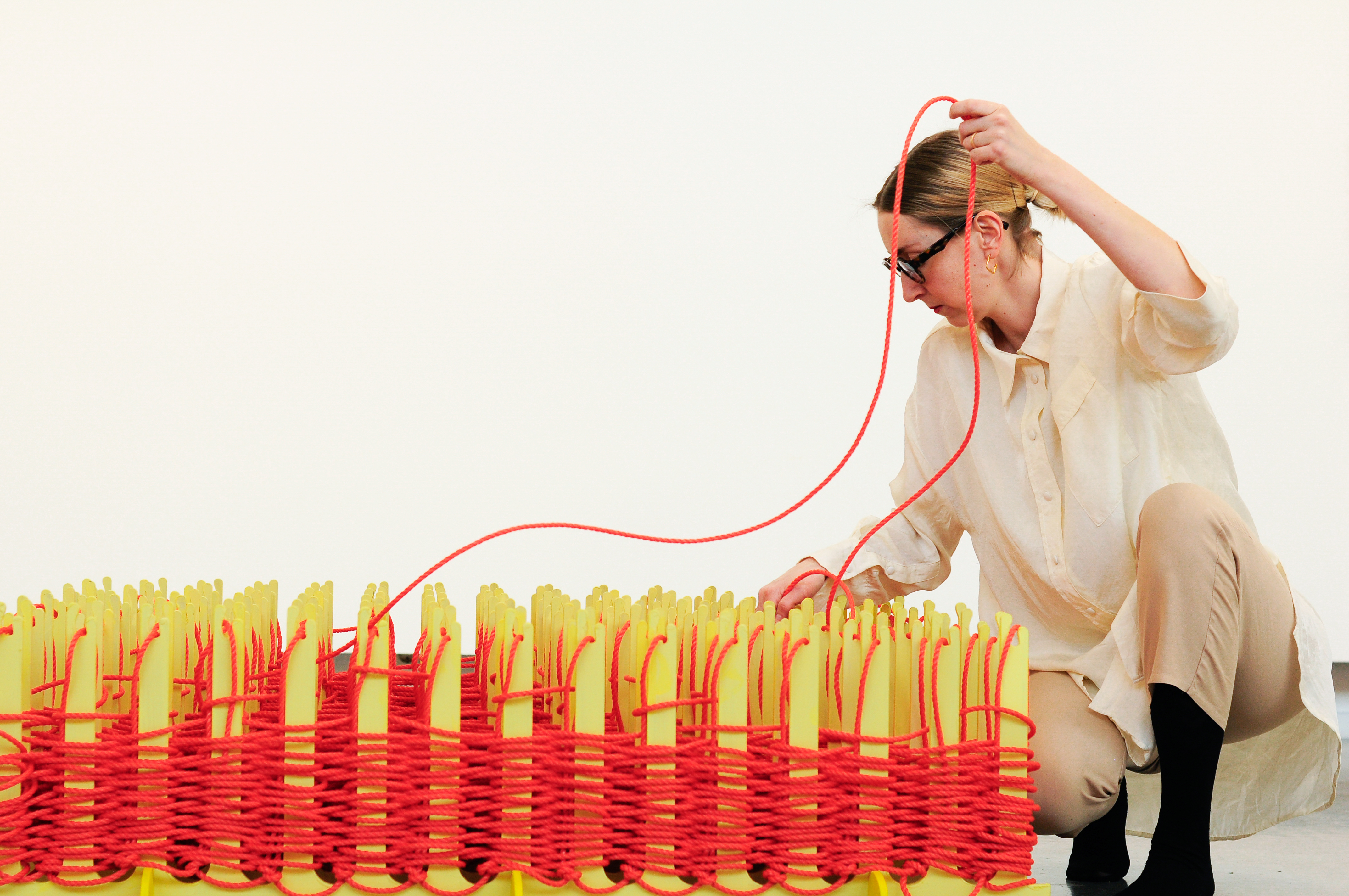

3. Weaving with Multiple Weft Ends

To address the time-intensive nature of manually guiding weft through

complex warp configurations, students at Pallas University of Applied

Sciences developed a technique for weaving with multiple weft ends

simultaneously. This method, documented in a student-made video, shows

how collaborative handling of weft threads can both accelerate

production and introduce aesthetic variations. It suggests possibilities

for scaling up MultiWeave in performance, educational, or small-scale

industrial contexts. (Figure 7, Figure 8-11)

{%vimeo 1091874640%}

Figure 7: MultiWeave performance by Sigre Kodasma, Liisi Tasso,

Hanna Maria Org, Christina Kasesalu. Video by Grete Käärma.

Figure 8: MultiWeave performance by Sigre Kodasma, Liisi Tasso,

Hanna Maria Org, Christina Kasesalu. Photo by Grete Käärma.

Figure 9: MultiWeave performance by Sigre Kodasma, Liisi Tasso,

Hanna Maria Org, Christina Kasesalu. Photo by Grete Käärma.

Figure 10: Removing the warp supports. Photo by Grete

Käärma.

Figure 11: Christina Kasesalu testing how wearable this structure

is. Photo by Grete Käärma.

4. Functional Applications: Svea Tisell and Furniture

Design

Swedish designer Svea Tisell has brought MultiWeave into the realm of

functional object-making. Her furniture line, showcased under the brand

Kryss, uses reclaimed climbing rope to create self-supporting structures

without frames. Through careful tensioning and the inherent strength of

the MultiWeave geometry, the furniture adapts subtly to weight and

pressure. These works highlight sustainability, mono-materiality, and

modularity, pointing to MultiWeave’s potential in environmentally

conscious design. A video from Tisell’s studio demonstrates her process

(Figure 12) and the adaptability of her pieces in real-world use.

Figure 12: Svea Tisell. MultiWeaving the chair.

5. Performance and Tool Enlargement: Mirjam Hemström

Farsi

Artist Mirjam Hemström Farsi has scaled up the MultiWeave tool to

architectural proportions, using it in performative installations where

the act of weaving becomes a public event. In her gallery exhibitions,

she constructs the fabric in real time, building both tension and

audience engagement. This performative use of MultiWeave transforms it

into a live medium for storytelling and spatial interaction. (Figures

13-15)

Figure 13-15: Mirjam Hemström Farsi at Tyresö konsthall, March,

2025. Photos by Linda Wardal.

6. Combining MultiWeave with Recycled Garments

During the 2024 Structure and Material course at Pallas UAS, textile

students explored the potential of combining MultiWeave with secondhand

garments. The results demonstrated how the technique can be used to

re-contextualize waste textiles by integrating them into structured

forms. These experiments produced hybrid pieces that blur the boundary

between garment, sculpture, and surface design (Figures 16-23).

Figure 16: Anželika Botšarova. MultiWeave structure integrated

into a secondhand garment. (Pallas UAS, 2025)

Figure 17-18: Gabriela Eva Eero. (Pallas UAS, 2025)

Figure 19: Janeli Liivak. (Pallas UAS, 2024)

Figure 20: Meribell Kivimets (Pallas UAS, 2025)

Figure 21: Helena Mai Posti (Pallas UAS, 2025)

Figure 22: Kristiin Talviste (Pallas UAS, 2024) Photo: Lisette

Laanoja.

Figure 23: Marilyn Piirsalu (2024). Photo Lisette

Laanoja.

7. Artistic Practice: “Listed Souls” at the 9th Tallinn

Applied Art Triennial

In my own artistic work, I continue to explore the narrative and

conceptual dimensions of MultiWeave. For the 9th Tallinn Applied Art

Triennial, I created “Listed Souls” using paper yarn and a warp support

tool made from bamboo sticks and fluted polypropylene. The fragility and

lightness of the material stood in contrast to the structural clarity of

the MultiWeave grid, creating a work that reflects on order, identity,

and impermanence. (Figure 24)

Figure 24. Kadi Pajupuu. Listed Souls. (2024)

8. MultiWeave in the Landscape: “Growth and

Decay”

My installation “Growth and Decay,” presented in the 2024 exhibition

Between Borders, Between Materials at the Estonian Museum of Applied Art

and Design, used biodegradable materials and soil within a MultiWeave

structure made of linen felt. Waste wool was added into the cavities,

and seeds were planted directly into the form. Over time, the piece

transformed, becoming part of the landscape and continuing to change

throughout the exhibition period. The work speaks to cycles of

regeneration, decay, and the interface between textile and ecology.

(Figure 25, 26)

Figure 25. Module made from linen felt, filled with waste wool,

soil and plants. Kadi Pajupuu. Growth and Decay.(detail, 2025). Photo

Marilyn Piirsalu.

{%vimeo 1091893239%}

Figure 26: Growth and Decay. Part of the installation. Video

Marilyn Piirsalu.

Conclusion

The recent developments in MultiWeave confirm it as an adaptable,

open-ended weaving system that bridges algorithmic logic, ecological

thinking, artistic expression, and social collaboration. Whether used to

encode mathematical problems, repurpose discarded materials, or build

living environments, MultiWeave challenges conventional boundaries

between textile, sculpture, and architecture. Its DIY ethos and

modularity continue to inspire new forms, tools, and communities of

practice.

Figure 1: Step-by-step creation of a warp loop field. (a) Vertical

support element; (a1) and (a2) indicate the upper and lower turning

points of the warp thread around the support; (b) shows the direction in

which the warp yarn is applied across the row. Drawing by Kadi

Pajupuu.

Figure 1: Step-by-step creation of a warp loop field. (a) Vertical

support element; (a1) and (a2) indicate the upper and lower turning

points of the warp thread around the support; (b) shows the direction in

which the warp yarn is applied across the row. Drawing by Kadi

Pajupuu. Figure 2: Diagram of weft path variations around and between warp

loops: (b) placement between warp rows; (c1) following the warp row

alignment; (c2) crossing rows; (c3) diagonal paths; (c4) zigzag

movement. The material’s thickness (d) is defined by the warp height and

number of weft layers. Weft positioning can also create vertical voids

or enclosed spaces within the structure. Drawing by Kadi

Pajupuu.

Figure 2: Diagram of weft path variations around and between warp

loops: (b) placement between warp rows; (c1) following the warp row

alignment; (c2) crossing rows; (c3) diagonal paths; (c4) zigzag

movement. The material’s thickness (d) is defined by the warp height and

number of weft layers. Weft positioning can also create vertical voids

or enclosed spaces within the structure. Drawing by Kadi

Pajupuu.